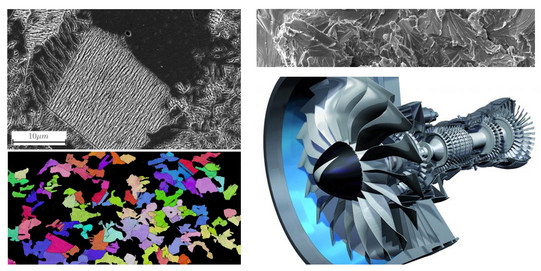

Microstructure and defect controlled additive manufacturing of γ-titanium aluminides for function-based control of local materials properties

The superior target is to understand the fundamental relationships between process parameters, solidification and cooling conditions and the microstructure formation and to systematically investigate its impact on the deformation and fracture behavior in additively manufactured γ-titanium aluminides (TiAl). A fundamental analysis of the fatigue deformation and fracture behavior and a correlation of the microstructure characteristics with the fatigue properties will be allowed due to a further development of the mechanism-based testing methodology for a resource-efficient characterization of the fatigue behavior of γ-titanium aluminides at room and high temperatures. Especially, the continuously transfer of the results in correlation matrices in order to realize a model-based description of the fundamental relationships between microstructure and properties will enable a transformation of the research results to additively manufactured γ-titanium aluminides in industry.

Duration: 2019 until 2022