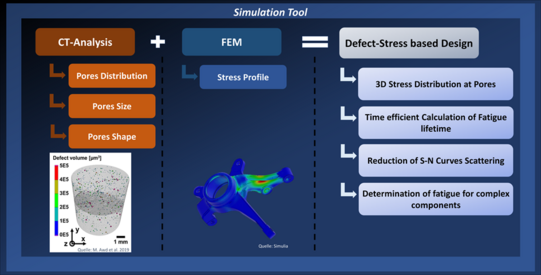

Development and validation of a computed tomography-based simulation tool for the fatigue life estimation of additively manufactured components

Fatigue lifetime is a critical value for additively manufactured components that are subjected to cyclic loading, therefore, it is essential to calculate it efficiently by considering all the factors, especially the porosity, that can affect it. In order to be able to analyse the porosity of additively manufactured parts, computed tomography (CT) can be applied. With the help of the CT analysis, there is the possibility of statistical evaluation of the pore distribution as well as the pore-related evaluation of the size, shape and position. By combining these pore characteristic parameters with the local stress profile, a defect and stress-based design with local concepts gets possible. The aim of this project is the development and validation of a simulation tool for the time and resource efficient calculation of the 3D stress distribution, with the help of which the real porosity and stress state of complex components can be determined and the effects on the fatigue properties can be assessed.

Duration: 2021 until 2022