Services

We offer the following services:

Metallography and microanalysis

- Micrograph preparation

- Light and electron microscopy (LiMi, SEM, FIB-SEM)

- Digital image analysis

- Chemical composition (EDX, OES)

- Computer tomography (CT)

- X-ray diffraction (XRD)

- X-ray fluorescence spectroscopy (XRF)

- Infrared spectroscopy (IR)

- Electrochemical corrosion testing

- Salt spray test

Mechanical material testing

- Hardness test

- Tensile test

- Impact and tearing test

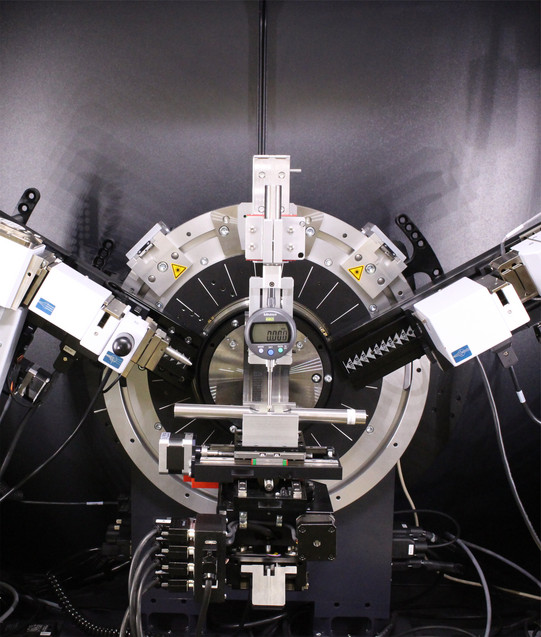

- Fatigue test, uniaxial and multiaxial

- Short-term strength to fatigue strength (LCF-VHCF)

- Temperature, corrosion and hydrogen environment

- Torsion, rotating bending and alternating bending test

- Short-term test procedure and statistical evaluation

- Electro-mechanical, servo-hydraulic, resonance and ultrasonic testing systems

- Furnaces, temperature, climate and corrosion chambers

Metrological condition monitoring

- Extensometer, video extensometer

- Digital image correlation (DIC)

- Camera and thermal camera systems

- Direct current and alternating current potential probes (DCPD, ACPD)

- Barkhausen noise

- Eddy current testing

- Acoustic emission

- High-frequency impulse measurement

Evaluation of lifetime and damage tolerance

- Influence of defects on performance (Effects of defects)

- Process-structure-property interactions

- Determination of (remaining) service life

Material modeling and simulation

Consulting and failure analysis

In addition to research and development (R&D) contracts, we offer acceptance tests and expert opinions.

![[Translate to English:] [Translate to English:]](/storages/zentraler_bilderpool/_processed_/c/1/csm_Kopfbild-H-Bahn_2b0e06bf0e.jpg)