Mechanism-correlated characterization of the deformation and damage behavior of thermoplastic-based hybrid laminates for property-oriented process development

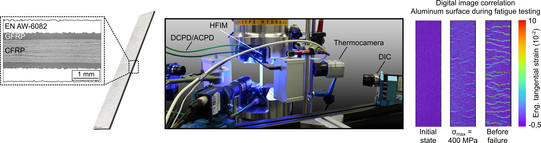

Hybrid laminates made of thermoplastic fiber reinforced plastic and metal offer mechanical advantages over non-reinforced plastic-metal composites and, unlike hybrid laminates with a thermoset matrix, can be subsequently formed and used for multi-variant, continuous mass production. The aim of the research project is to describe the interaction between the consolidation process, structure, and the achievable fatigue and crack propagation properties of hybrid laminates made of carbon fiber reinforced thermoplastic and EN AW 6082. By simultaneously applying optical deformation, electrical resistance, thermal and acoustic emission measurement methods in fatigue tests, the Chair of Materials Testing Engineering characterizes the material-specific fatigue behavior.

Duration: 2019 until 2021