Cross-process modelling in production engineering

The SPP 2476 research project involves close interdisciplinary collaboration between the fields of manufacturing, materials, measurement and control engineering. The aim is to develop scientific principles for the process-integrated control of properties in manufacturing processes such as forming, cutting and welding, in order to produce high-performance components. This allows controllable manufacturing processes to be designed based on methods, manufacturing errors to be detected, and microstructure development to be investigated throughout the entire process chain using robust measurement systems and inline sensors.

Project duration: 2025 to 2028

Subproject: Methodology for holistic process chain analysis and modelling using the example of bipolar plate manufacturing

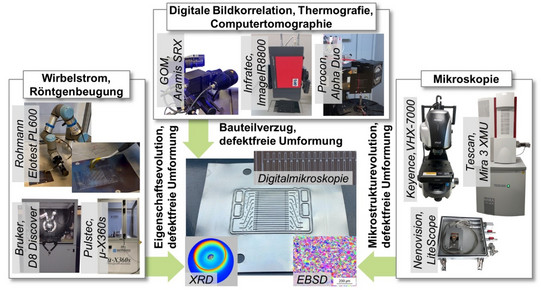

The aim of the project is to identify the most important control and disturbance variables along the process chain and their influence on product quality. The relationships between these control variables must be investigated in order to obtain defect free bipolar plates (BPP). An inline sensor must be developed to meet the quality criteria. Process errors such as thinning of the sheets, wrinkling, cracking, flatness deviations, and dimensional errors must be controlled using modern and innovative measurement technologies.