Damage model for service conditions

The CRC/Transregio 188 Damage Controlled Forming Processes is a joint long-term research project with participation of RWTH Aachen, BTU Cottbus-Senftenberg, TU Dortmund University and the Max-Planck-Institut für Eisenforschung. The overall objective is to investigate damage nucleation and evolution in hot and cold forming on multi-process and multi-scale level by merging of competences in the areas of forming technology (A-projects), materials science (B-projects) and mechanical material modeling (C-projects). Strategies are developed to permanently improve the performance of components produced by shaping technology by adjustment of damage profiles through optimization of load paths.

Duration: 2017 until 2028

Consortium: 3 universities, 1 research institute

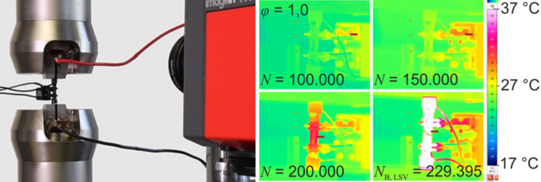

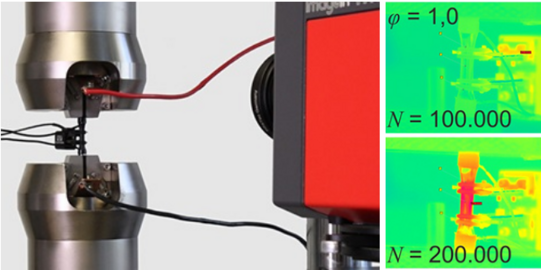

Subproject C01: Thermo-mechanical coupled damage model for operational loading conditions – predicting the operating time of formed components

This project aims to predict the behavior of components made of 16MnCrS5 under operational loading conditions. Particularly, the influence of ductile initial damage caused by a previous forming process is analyzed. For that purpose, a novel characterization of microstructural defects is elaborated and combined with a novel thermo-mechanical coupled macroscopic constitutive. By doing so, even complex loading paths – including those characterized by axial-torsional loading – can be investigated in a first step. Subsequently, improved loading paths can be virtually designed

Please confirm video activation.

After activation, cookies will be set and data is sent to YouTube (Google).

To the Google Privacy Policy