Greybox models for high-performance machining

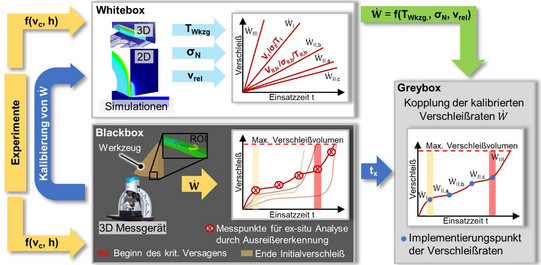

To qualify coated tools for high-performance machining, greybox models consisting of deterministic models (whitebox) and data-driven models (blackbox) are being developed in the priority program 2402. For this purpose, methods and expertise from materials and production engineering are merged. The models are intended to describe the transient system behavior when using such tools.

Project duration: 2023 until 2026

Consortium: 20 research institutes

Subproject: Greybox-model-based prediction of the wear evolution of coated tools by experimental and model-driven identification of relevant load horizons

The aim of the sub-project is a greybox prediction of wear through experimental and model-driven identification of relevant load horizons. To achieve this, extensive experimental investigations are carried out. Data-driven anomaly detection monitors process forces and acoustic emissions in real time to identify critical load horizons (black box). Ex-situ measurement techniques reveal correlations between in-situ data and tool condition. Numerical simulations (white box) supplement non-measurable variables, validated by experiments. Based on characterized wear, the wear rate is adjusted for precise greybox modelling. This allows the behavior of the carbide tools and their stochastic failure to be predicted precisely over the service life.