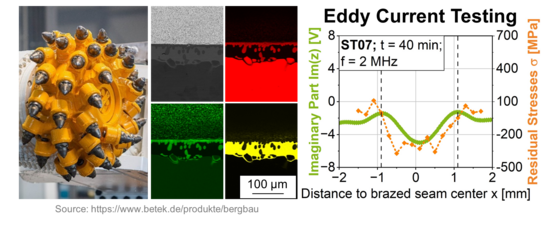

Microstructure-based development of a corrosion-resistant copper-based hard metal/steel brazed joint to ensure a 50% increase in lifetime for agricultural, earth-moving and mining components

In agricultural machinery and mining industries, the resistance of tools, such as plows or tunnel drills, is increased by hard metal inserts. For this purpose, the hard metal inserts are brazed onto the tools, which are made of steel. But hard metal and steel differ greatly in terms of their thermal expansion coefficients, which leads to high residual stresses during the cooling phase of the brazing process. In addition, the brazed joints are exposed to weakly acidic media due to their field of application. The aim of this ZIM project is, to ensure an optimization of the hard metal/steel brazed joints in cooperation with Löttechnik Burkhard GmbH & Co. KG. For this purpose, the brazing process will be adapted to the findings from mechanical fatigue tests and microstructural investigations of the hard metal/steel brazed joints and a non-destructive testing process will be developed with the aid of eddy current testing, which should enable a resource-saving and time-efficient quality management.

Duration: 2022 until 2024